Ý nghĩa kỹ thuật của Die Cut Tape trong các ứng dụng liên kết chính xác

Trong thế giới biến đổi không ngừng của kỹ thuật chính xác và điện tử, nhu cầu về các giải pháp kết dính hiệu quả và đáng tin cậy là tối quan trọng. Băng keo cắt theo khuôn mẫu (die cut tape) đã trở thành một ứng dụng quan trọng trong các lĩnh vực này, với chất lượng, độ đồng đều và tính linh hoạt mà phương pháp truyền thống không thể đạt được. Bài viết này thảo luận về tầm quan trọng kỹ thuật của băng keo cắt theo khuôn mẫu đối với khả năng cắt chính xác trong kết dính, các khuôn cắt tùy chỉnh và tính tương thích của keo dính.

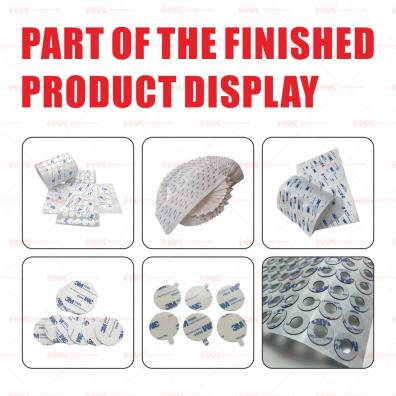

Các Kỹ Thuật Cắt Khuôn Tùy Chỉnh Để Đảm Bảo Kích Cỡ Băng Keo Đồng Đều Trong Ngành Điện Tử

Trong lĩnh vực điện tử, xu hướng hiện nay là hướng đến việc thu nhỏ kích thước và gọn nhẹ, điều này cũng trở thành yếu tố quan trọng hàng đầu đối với công nghệ kết dính. Việc đáp ứng các yêu cầu này thông qua quy trình cắt khuôn mẫu tùy chỉnh đã chứng minh được tính thiết yếu nhờ vào độ đồng đều về kích thước băng keo và sự chính xác cao. Các quy trình này trang bị cho các nhà sản xuất khả năng xử lý các kích thước băng keo đáp ứng chính xác các yêu cầu về kích thước của các linh kiện điện tử phức tạp.

Cắt khuôn theo yêu cầu đóng vai trò trung gian giữa nguyên vật liệu và sản phẩm cuối cùng, đảm bảo mọi thành phần của băng dính đều phù hợp với cấu trúc của thiết bị. Độ chính xác này rất quan trọng vì ngay cả sai lệch nhỏ nhất cũng có thể gây ra các vấn đề liên quan đến hiệu suất hoặc lắp ráp. Nhờ thiết bị và phần mềm hiện đại, các nhà sản xuất có thể thực hiện cắt ở mức độ chính xác đến micrôn và điều này có ý nghĩa rất lớn trong điện tử mật độ cao nơi không gian bị giới hạn.

Ngoài ra, việc cắt khuôn theo yêu cầu còn tăng hiệu quả trong sản xuất và ngăn lãng phí. Phương pháp cắt truyền thống có thể tốn thời gian và thiếu chính xác, dẫn đến phát sinh phế liệu. Băng dính được cắt khuôn chuyên dụng có thể được sản xuất đúng số lượng và kích thước mong muốn, từ đó giảm chi phí và hạn chế tác động đến môi trường.

Tác động của Tính tương thích của Keo dính đến Hiệu suất của Băng cắt khuôn trên vật liệu Nhựa

Tính tương thích giữa keo dính và vật liệu nền là yếu tố quan trọng đối với hiệu suất của băng keo cắt die trong các ứng dụng sử dụng băng keo như một chất kết dính. Vật liệu nền trong hầu hết các trường hợp là loại nhựa, điều này nói chung sẽ gây ra những khó khăn đặc biệt vì chúng có đặc tính khác nhau. Việc xác định tính tương thích của keo dính là rất quan trọng để tạo ra mối kết dính vĩnh viễn và bền bỉ.

Mức năng lượng bề mặt của các loại nhựa khác nhau sẽ ảnh hưởng đến khả năng lan tỏa và kết dính của keo lên bề mặt. Nhựa có năng lượng bề mặt cao như ABS hoặc polycarbonate thường tương thích tốt hơn với keo dính, cho phép kết dính dễ dàng với nhiều loại keo khác nhau. Ngược lại, các ống làm từ nhựa có năng lượng bề mặt thấp như polyethylene hoặc polypropylene chỉ có thể được kết dính bằng các loại keo được thiết kế đặc biệt để đảm bảo khả năng kết dính chính xác.

Việc lựa chọn keo dán phù hợp cho băng keo dập chết cần lưu ý đến các yếu tố khác ngoài môi trường, khả năng chịu tải và loại nhựa cần sử dụng keo dán. Ví dụ, khi một thiết bị được thiết kế để sử dụng ngoài trời, keo dán cần có khả năng chịu được tia UV và sự thay đổi nhiệt độ. Tương tự, ứng dụng có thể yêu cầu khả năng chống hóa chất hoặc độ ẩm, điều này sẽ ảnh hưởng đến loại keo dán được sử dụng.

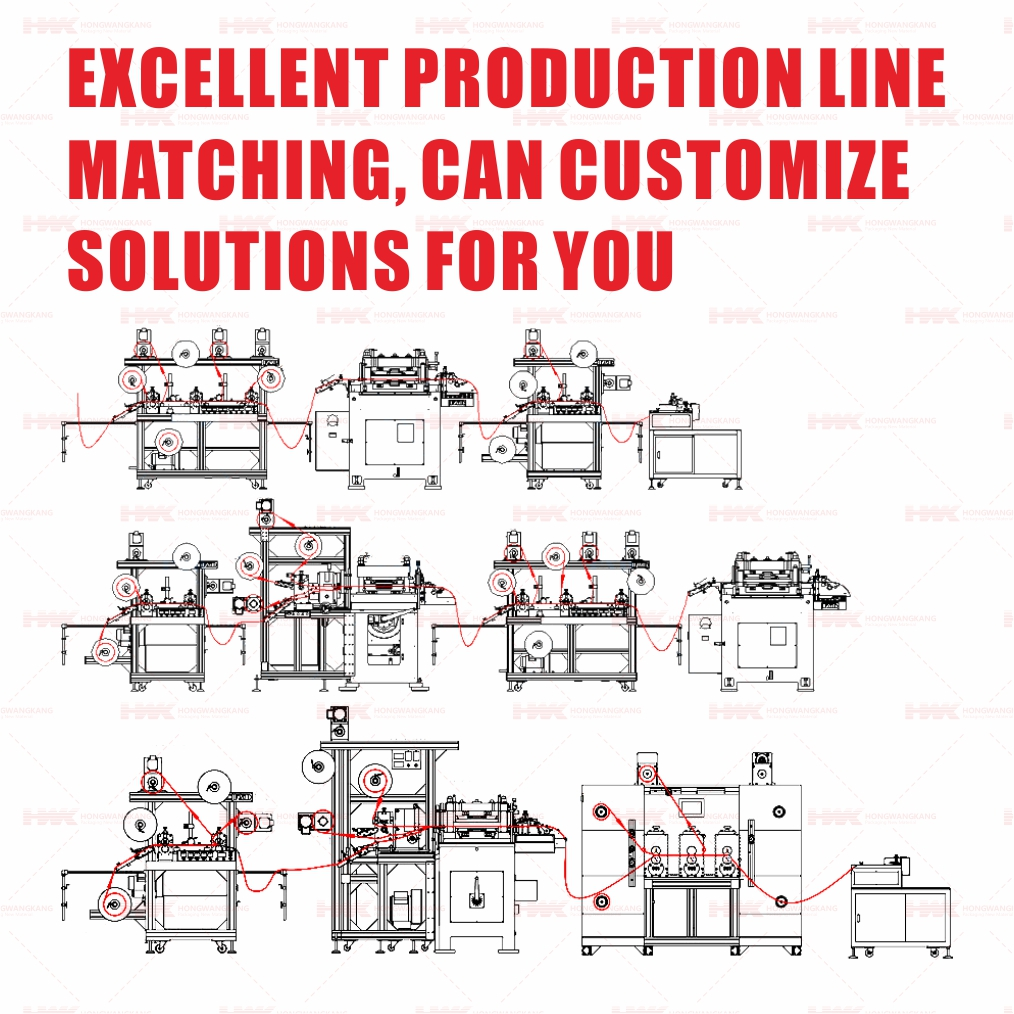

Để tạo ra một giải pháp tùy chỉnh, các nhà sản xuất băng keo dập chết thường xuyên tham vấn các chuyên gia về keo dán nhằm tạo ra một giải pháp hoạt động hiệu quả trong những thông số kỹ thuật và điều kiện cụ thể. Điều này cho phép lựa chọn chính xác băng keo dập chết cần sử dụng, nhưng vẫn cần đảm bảo hiệu suất duy trì trong suốt thời gian sản phẩm hoạt động.

Công thức keo dán không phải là yếu tố duy nhất ảnh hưởng đến hiệu suất của băng keo cắt die; phương thức ứng dụng cũng có thể tác động đến hiệu suất của keo dán. Độ bền và sức mạnh của mối kết dính có thể được cải thiện thông qua các kỹ thuật như sử dụng nhiệt hoặc áp suất để kích hoạt, và một lần nữa, điều này cũng cho thấy vai trò quan trọng của tính tương thích để tạo ra kết quả tốt nhất.

Kết luận lại, có thể khẳng định rằng băng keo cắt die đã trở thành một thiết bị không thể thiếu mới trong ngành công nghiệp kết dính chính xác, đặc biệt tập trung vào ngành điện tử. Việc tối ưu hóa độ chính xác về kích thước băng keo đạt được thông qua quá trình cắt băng theo khuôn die tùy chỉnh và lượng chất thải được giảm thiểu đáng kể thông qua các kỹ thuật này, đồng thời cũng nâng cao các đặc tính hiệu suất của thiết bị. Trong khi đó, tính tương thích với keo dán, đặc biệt là sự phù hợp với nhựa vẫn rất quan trọng trong bối cảnh các yêu cầu kỹ thuật ngày càng cao hiện nay trong lĩnh vực kỹ thuật, vì băng keo cắt die cần đáp ứng được các tiêu chuẩn kỹ thuật cao.

Do nhu cầu về các cấu trúc thu nhỏ tinh vi hơn và tính tùy chỉnh cao hơn, sự phát triển bổ sung của công nghệ băng keo cắt die chính xác sẽ đi kèm với sự tiến bộ của công nghệ. Khi ngày càng nhiều đột phá được thực hiện trong lĩnh vực khoa học cắt die và khoa học keo dán, điều này tất yếu xảy ra, ngành công nghiệp có thể kỳ vọng sẽ thấy sự tích hợp ngày càng nhiều các yếu tố này, từ đó mang lại hiệu suất tốt hơn cũng như mở ra những cơ hội mới trong thiết kế và hiệu năng.

EN

EN

AR

AR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SR

SR

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

GA

GA

BE

BE

IS

IS

HY

HY

BN

BN

LA

LA

MN

MN

SO

SO

MY

MY

KK

KK