בעולם ייצור דינמי, שבו יש צורך להימנע מהצגת סדקים על פני השטח כדי להבטיח את יעילות המוצרים ושביעות הרצון של הלקוחות. אחת הפתרונות שנפוצה בשנים האחרונות היא השימוש בفيلם צמוד עצמי מסוג PET (פוליאתילן טרפת'לט). הפילם הצמוד העצמי מסוג PET ידוע בזכות עמידותו הגבוהה, שקיפותו וגמישותו, תכונות שמועילות להגנה מפני שטחים בתעשייה כלשהי, לדוגמה: ייצור, תקשורת, בנייה, תחבורה, רכב, חלקי חשמל, מטוסים, ניסויים קליניים ועוד. כשמדברים בעד השימוש בפילם צמוד עצמי מסוג PET כדי לכסות פני שטח, נבחן את הדיון על עמידותו בפני סדקים ועל תכונות העיצוב שלו, שמאפשרות לו להידבק בקלות.

עמידות בפני סדקים: תפקיד ה-PET Film בשמירה על פני שטח מחומרים צבעוניים וממוצפים

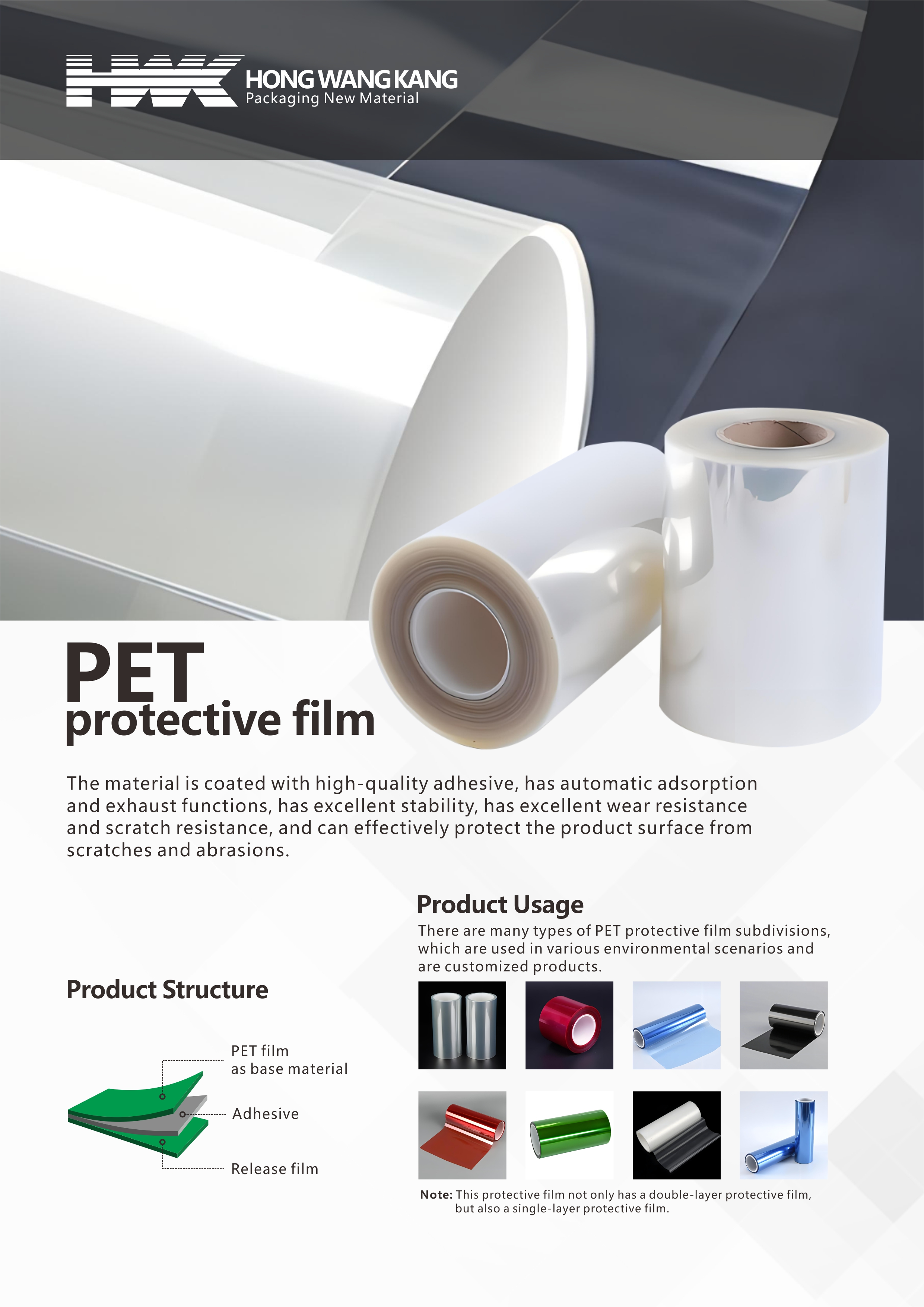

הסיכוי לשריטות ולבלאי פנים הוא אחד המאפיינים המרכזיים של תהליכי הייצור. קיצוניות זו בולטת במיוחד ביישומים מוקדמים/צבועים, שכן פגיעה מינימלית עשויה לפגוע במבנה הקוסמטי ואף בפעילות הפונקציונלית של המוצר הסופי. פילם צמוד העשוי מ-PET מהווה מכשול מצוין בפני סיכונים אלה, בזכות תכונות השריטה המובנית בו.

החוזק והגמישות של פילם ה-PET נובעים מהמבנה הפולימרי העבה שלו עם מחסום מוצק שיכול לעמוד בחיכוך ובהשפעות בעת שהוא מטופל, מובא ומת ensambl. המחסום הזה נגד קריצות מאפשר לשטח צבועים ומוחשטים לשמר את צורתם הטובה ביותר לאורך תהליך הייצור. למשל, ברכב ניתן לכסות את החזית והפנים של רכב בשכבת פילם PET בתעשייה האוטומotive, מאחר ש materiał הזה מגן מפני נזקי רכב הנובעים ממכשורים, התקנים והסביבה. באופן שווה, באלקטרוניקה, פילם ה-PET משמש לכסות מסכים ותצוגות כדי למנוע כתמים ולשמור על הבהירות של המסכים והתצוגות.

בנוסף, סרט הדבקה עצמי של PET מספק משך זמן ארוך יותר של משטחים שעליהם הוא מותקן. מניעת שריטות וסוגי פגיעה אחרים מאפשרת לייצרנים להציג מוצר שנראה טוב יותר אך גם שומר על תפקודיות לאורך זמן. הדבר אינו רק משפר את חוויית המשתמש אלא גם את הקיימות של תהליך הייצור על ידי הפחתת פסולת ועבודות תיקון חוזרות.

שכבת שחרור פשוטה: תכונות עיצוב של סרט הדבקה עצמי PET ליישום יעיל

סרט הדבקה עצמי של PET קל לשימוש בנוסף לתכונות ההגנה שלו. המאפיין המדהים של חומר זה הוא שכבה קלילה של שחרור, מה שעושה את תהליך היישום וההסרה חלקים ולכן חוסך בעלויות של זמן וכוח אדם במהלך הייצור.

השכבת שחרור קלה (ER) היא היבט אחד בעיצוב של סרט ה-PET שמאפשרת הסרה פשוטה ולא משאירה שאריות לאחר תקופת ההגנה. טכנולוגיה זו שימושית במיוחד בעבודה בתנאי ייצור המוני, כאשר היעילות היא בעלת עדיפות. היעילות בה которой הסרט מוסר במהירות ובצורה נקייה מבטיחה שהקוים לייצור יוכלו לשמור על קצב יציב ללא השהיות שנובעות מנקה טח שנדרשת זמן רב.

בנוסף, היעילות בה מונח סרט ה-PET מקטינה את הסיכוי לפגיעות הנגרמות במהלך תהליך היישום עצמו. עיצוב הסרט מקטין את היווצרות בועות אוויר וכפפות, ומביא לידי ביטוי שכבה הגנתית שמתאימה באופן מדויק ו אחידה לפני השטח. דבר זה מכסה את האזור בצורה מקיפה ומגביר את האפקט ההגנתי של הסרט.

למפיקים גם נוחה היעילות הרבת-תכליתית של סרט הדבקה מ-PET. הדבקים, הסיום והעוביים נמצאים גם כן בפניהם, וליצרנים יש את ההזדמנות לבחור בסרט המתאים ביותר שי đáp לדרישותיהם. האם דרישה כזו נבעה מהצורך בדבקת דבק חזקה כדי לאפשר הדבקה על סוגי משטחים מאתגרים מסוימים, או מהצורך בסוג דבק עם דבקת נמוכה, או מהצורך בזמני הדבקה כדי להתאים סוגים מסוימים של חומרים רגישים – ניתן לעצב את סרט ה-PET כך שיספק את התאמה למגוון שימושים זה, ויביא להרחבת תפקודיותו בתעשייה הייצורית.

סיכום

סרט הדבקה מסמך PET זכה להכרה רבה בזכות תכונותיו outstanding של עמידות בשריטות ובזכות תכנון שמייצר נוחות רבה בשימוש. הסרט מונע שריטות, מגן על משטחים צבועים ומוחשטים, ומבטיח שהמוצרים יעברו את רמת המינימום הדרושים כדי לעמוד בסטנדרטים הגבוהים ביותר. שכבות ההוצאה הפשוטות שלו לא רק שmakes את תהליך ההדבקה קל יותר - הן מקילות את תהליך הייצור על ידי הקטנת הזמן והמאמץ הנדרשים בשלב ההדבקה והשליפה. במטרה לענות על הדרישות השונות של תעשיית הייצור, סרט הדבקה מסמך PET הינו בחירה חשובה ומעשית לשיפור הגנה על משטחים, מה שמוביל לייצור של מוצרים איכותיים ועמידים.

EN

EN

AR

AR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SR

SR

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

GA

GA

BE

BE

IS

IS

HY

HY

BN

BN

LA

LA

MN

MN

SO

SO

MY

MY

KK

KK