The die cut tape by HWK is a pillar of electronics and assembly bonding offering high precision and consistency to suit industry requirements. Supported by the factory-direct sales model of the company, stringent adherence to SGS and ISO 9001 standard, and emphasis on custom solutions, this tape is reputed to provide reliable performance in a variety of electronic bonding conditions.

Custom Shapes and Sizes for Automated Manufacturing Processes

HWK provides die cut tape in bespoke shapes and sizes, bespoke to meet automated assembly procedures in electronics assembly. This flexibility removes manual trims and condenses production efficiency and minimizes errors. Bonding small electronic components, or greater assembly objects: The custom-cut designs are in harmony with the automated manufacturing processes, which is one of the reasons HWK is dedicated to facilitating the efficient manufacturing process through the user-friendly product design.

Ensuring Adhesive Compatibility with Sensitive Electronic Substrates

HWK is focused on the adhesive compatibility on fragile electronic substrates in its die cut tape development. Items such as its die cut copper foil tape with conductive adhesive have been designed to attach firmly without breaking the fragile electronic components or affecting their operation. This compatibility goes further to self-adhesive PET protective film variants, which guarantees bonding and protection are in parallel without impairing performance of sensitive electronic substrates- to the rigid demands of electronics manufacturing.

Heat Resistance for Stable Performance in Electronic Assembly

HWK die cut tape has heat-resistant versions, including its own custom die cut high temperature tape, which is built to sustain consistent operation in an electronics assembly workflow with hot temperatures applied. This is thermal resistant to allow the tape to resist degradation or adhesive failure during soldering or other heat-exposed processes, and to achieve uniform bonding even in the most hostile manufacturing conditions. Quality certifications received by HWK support this characteristic, making it very reliable in sensitive electronics applications.

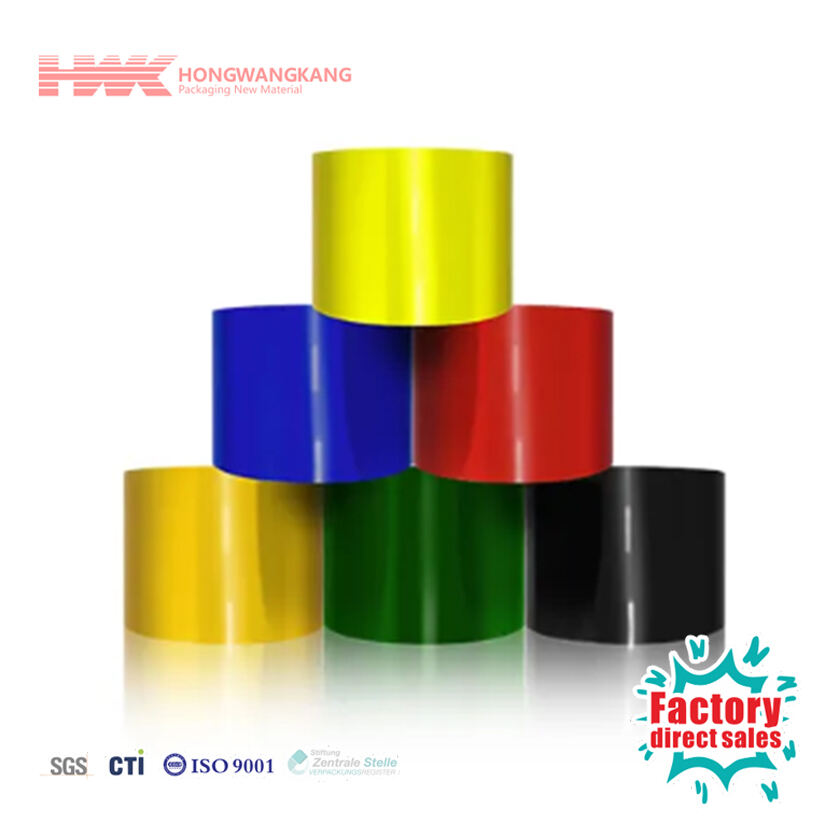

Versatile Material Options for Diverse Bonding Needs

The die cut tape cover offered by HWK is made of various versatile materials to meet various electronics/assembly bonding requirements. With high-density EVA foam die cuts to cushion and protect, to reusable nano adhesive pads to mount phones and other electronic accessories to the automotive, each material is chosen to fit certain bonding needs, be it shock absorption, reusability, or surface protection. This flexibility guarantees that HWK die cut tape is capable of adjusting to many different types of electronic assembly.

In short, the die cut tape produced by HWK is superior in electronics and assembly bonding by providing customizability, compatibility with substrates, heat resistance, and versatility of materials. Backed with the stringent quality and factory-to-factory efficiency, it represents the commitment of the HWK to the provision of accurate and repeatable solutions that respond to the demands of specific electronic production.

EN

EN

AR

AR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SR

SR

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

GA

GA

BE

BE

IS

IS

HY

HY

BN

BN

LA

LA

MN

MN

SO

SO

MY

MY

KK

KK